There are a lot of very good reasons to choose digital printing for your packaging – it’s affordable, fast to produce and a great choice for small orders.

But, if we’re being honest; it doesn’t suit every packaging design. Like any print method, digital printing has some areas where it excels and a few limitations.

We wanted to make sure that you understand what to expect from digital printing, so we’re sharing a few examples.

What does digital printing do well?

We’ve watched more than one box roll off our digital printer and been highly impressed with the results. Usually, that’s because the box design is perfectly suited to digital printing.

So, what should you focus on to achieve a high-quality digital print? Here are 3 examples.

Shading and detail

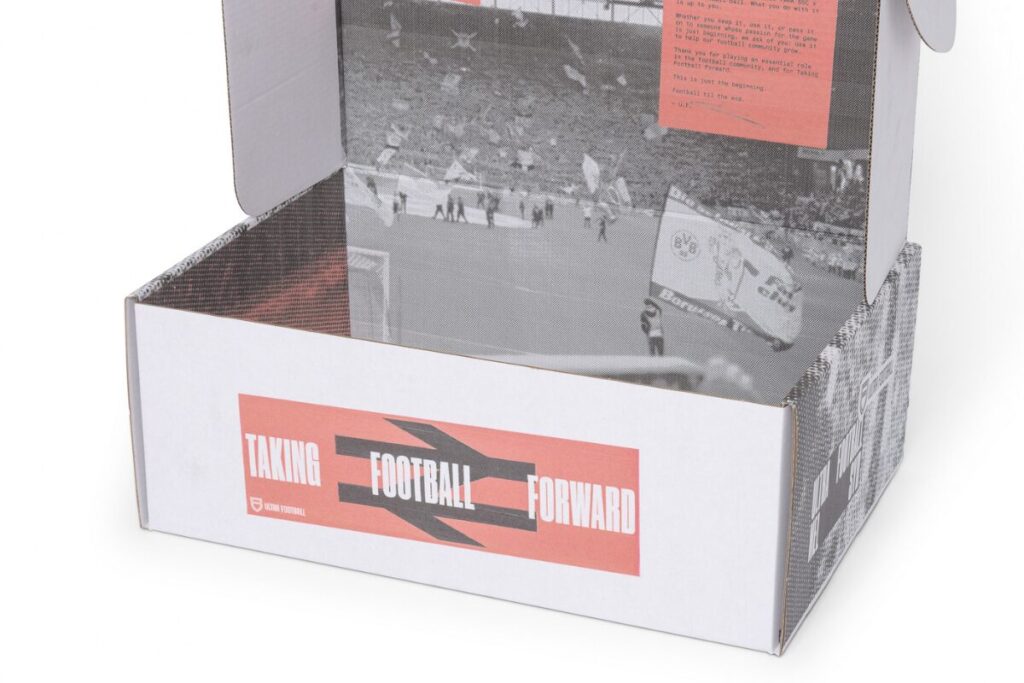

As a four-colour print process, digital printing is great at getting multiple shades or tones of a single colour. The box pictured below is a good example of this at work. The design features a repeated image in different shades of grey.

Complex imagery

If your box design uses TIFF, PNG or JPEG image files and graphics – then digital print is an ideal choice. It’s one of the few printing methods that is capable of producing complex imagery, with lithographic (offset) printing being the next most popular.

Digital printing is typically more affordable than offset printing because it has no setup or tooling costs. We often say that digital produces near-perfect results for a much better price.

Strategic colour printing

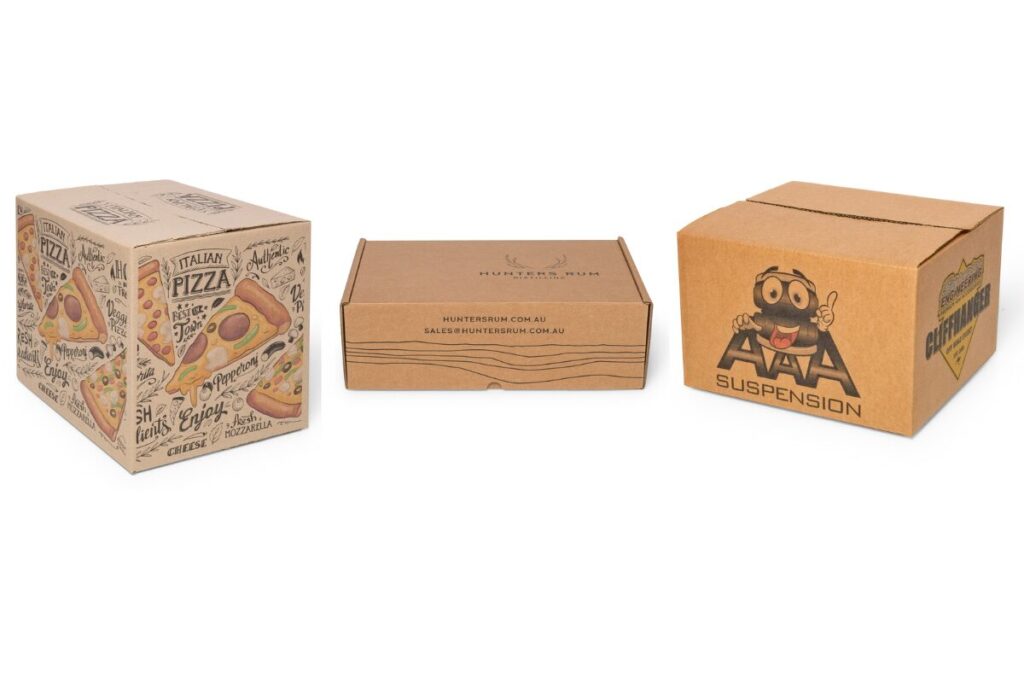

This is probably our biggest tip when it comes to digital printing: the designs with the most impact use the board as their base. What do we mean by that? Well, here are 3 examples.

Each of these boxes have left plenty of negative space, which helps the designs they do feature stand out even more.

They’ve also avoided what we see as the biggest mistake you can make with digital printing – full colour coverage. That’s better left for other print methods, like flexo.

Coated vs uncoated cardboard: texture & finish

Every box you order from Echo Cartons or Echo Boxes Online is printed on uncoated cardboard. That means that the print finish is going to appear soft and organic, with the texture of the box still visible beneath the ink.

We wanted to mention this because some customers are looking for a flawless or glossy finish. That’s only possible with coated cardboard, which offers a smooth surface for printing, and it’s what you might picture when thinking of glossy brochures or some folding cartons.

Digital print on uncoated board is a very different process. It’s not about competing with that style, but about offering its own strengths: a natural, tactile finish that feels authentic and has real character.

Digital Printing on Uncoated Board – What to Expect

What it is:

- Short-run, high-quality packaging that’s fast and affordable

- A natural, tactile finish that feels authentic and distinctive

- Perfect for SMEs who need flexibility without bulk orders

What it isn’t:

- A glossy, brochure-style litho print

- Designed for full-colour flood coverage

- The cheapest option for high-volume runs

The key reason we’ve chosen uncoated cardboard is that it’s an affordable material. Our goal is to support SMEs with high-quality packaging, and that includes helping them achieve great results in smaller budgets.

For many SMEs, lithographic packaging isn’t an option. The costs are high, and some suppliers won’t even consider short runs. That’s the gap that Echo Cartons, through our digital print arm, Echo Boxes Online, fills. With our digital printing, you can achieve high-quality, short-run packaging that looks professional, aligns with your budget, and is ready in days rather than in weeks. The finished product, however, doesn’t look the same as lithographic printing on coated cardboard. Not better or worse, just different, as they are distinct processes.

We have a couple of examples below that we believe highlight the natural finish on uncoated board well. You might notice that in some designs, the ink sinks into the cardboard which gives an even softer appearance.

Printing on brown vs white cardboard

Finally, we wanted to compare the print finishes you can achieve from both brown and white cardboard. We wouldn’t say one is better than the other, but they do achieve different results.

If you want your box design to have vibrant colours, we often recommend white board. The high-contrast helps your colour printing stand out.

Another great option is black print on white board. These designs tend to come out clear and uncluttered with a highly professional finish.

For a more rustic or natural look, it’s hard to go past brown board. It’s a popular choice for brands that are keeping things simple with their logo and minimal graphic design.

It does work well with colour design, but it’s important to remember that the colours will appear softer on the brown background.

How does digital printing compare with other methods?

If you’re worried that your design is not the right fit for digital printing, there are other options available.

Many designs work well with flexo printing, which we specialise in at Echo Cartons. Then there’s offset printing, which is not something we do – but it might be the right choice for your design.

Compared to flexo printing

If there’s one thing that flexo printing does better than any other method; it’s rich, single-colour designs. A great example is the box pictured below – digital printing is not going to get the same intense black colour, because it’s just not designed for it.

The other thing this box design does well for flexo print is the simple artwork. Flexo is perfect for printing text and line art, but doesn’t suit complex imagery.

We covered the key differences between digital and flexo printing in more detail on the blog.

Compared to offset/lithographic printing

Lithographic or offset printing is a similar process to flexo which uses large printing plates to transfer your designs. It’s a popular printing method known for achieving flawless, glossy results – but these do come at a higher cost.

A key difference between digital and offset printing is the order quantities. It’s a well-known fact that the costs for offset printing go down the more you order. Typically, bulk orders for thousands of boxes get the best price per print.

In comparison, digital printing is a method that’s ideally suited for short runs – starting at 25 boxes at Echo Boxes Online and going up to around 500 units.

As specialists in small runs for local businesses, we aim to produce great quality boxes in realistic budgets. That’s why we’ve chosen to invest in digital and flexo printing – both options can produce professional results, without requiring bulk orders or high-end budgets.

Sometimes, a customer comes to us with a design that we believe is better suited for a glossy print method, like offset. We may be able to advise on how they can alter their design to fit digital or flexo printing methods. Otherwise, we might recommend they find another manufacturer.

At the end of the day, our goal is the same as yours – producing beautifully branded packaging that makes your business stand out.

Quality packaging, made in Melbourne

Echo Cartons have over 25 years’ experience in corrugated box manufacturing. We pride ourselves on our friendly team, fast service and great quality boxes. Based in Braeside, Melbourne; we’re the packaging supplier of choice for Australian SME’s. When you’re ready to start a packaging order – simply request a quote.